Air motors need to be powerful, compact, and well designed. That’s how our motors are.

Having a knack for innovation, we design and manufacture cutting-edge rotary vane motors.

Building pneumatic motors and their parts and accessories for years, we take pride in offering the best vane air motors in terms of quality, power, speed, and longevity of the service life.

Our durable vane air motors can be used in a variety of products and machines. A complete range of pneumatic motors are available for use in industrial machinery, tools, electric equipment.

We offer a series of rotary air motors, varying in RPM, torque, and power. Whatever your needs, our powerful, high-speed motors will cater to them all.

An air motor does not need electricity. A compressor compresses the air which is pumped into the vane motor. The motor in turn produces mechanical energy. Here’s what sets our motors apart from others:

We also can also manufacture an oil-free product for your specific use.

Simplicity is the first trait of great technology. Our simple, well-balanced design ensures that the vane motor is easy to maintain and clean. Because of this simple design, one can easily replace spare parts that need to be changed. This is our service offer.

Unlike electric motors, pneumatic vane or piston motors neither require electrical energy nor produce sparks. They are a safer choice in the volatile atmosphere and for mining applications. You only need a compressor or several compressors that can be located outside this area.

Our ATEX-certified vane motors are explosion-proof and self-cooling. They can also endure a high pressure of water without corroding or shattering.

We have a broad range of air motors having different speeds, torque, power, and size. Although there are various models for multiple purposes, you can vary the speed of any vane air motor by adjusting the flow of air. Other neutral gas (nitrogen, argon…) can also be used.

Our light, weightless motors can be installed effortlessly on any kind of equipment or machinery. They are compact and robust. We also provide related accessories like brakes, reduction gear, and controllers so that the rotary vane motors are the solutions to your multiple requirements.

Our innovative design makes the vane motors compact and light-weight. They can, thus, used in hand-held tools and other equipment where a large electric motor won’t fit.

Moreover, our vane motors are made of stainless steel, which prevents them from corrosion, increasing their service life. Our products also include oil-free and oil-injected models.

Vane air motors are ideal for a multitude of industrial and mining applications. Depending upon your use, we have a series of models tailored for different products and machines. They vary in speed, torque, power, lubrication, etc. So choose the one designed for your needs.

Do not hesitate to contact us to get more information about all various ranges of pneumatic motors, air motors, and even double rotor air motor.

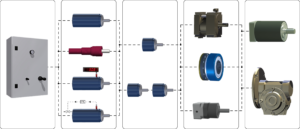

Assembling options of our air motor’s range

From hand-held tools and hydraulic pumps to industrial machinery, air motors are used to produce mechanical energy in various places. Though there is a wide range of their applications, air motors are most commonly used for:

Hand-held tools require a small, compact motor having high speed, so a vane or piston air motor does the job. Their usage ranges from drills, grinders, and torque wrenches to sanders, dental drills, and tyre changers.

Since they offer some advantages over their electric counterparts, air motors are used in various industries for tasks such as starting natural gas engines. Compressors also use electric or gas motors to compress air.

Apart from the pipe processing industry, vane motors have applications in the food packaging industry. Air motors can be fitted in magnetic drive pumps. You may use these motors to power liquid pumps that move hydraulic fluids.

In a nutshell, our air motors are reliable, safer alternative to the electric ones. We don’t sell a single product; we provide complete pneumatic solutions for your requirements.

A competitive review will allow you to find out about key players in the industry. Our competitors are Atlas Copco, Deprag and Modec.

What we want to highlight is the quality of our service. This what a comparator does not provide: to compare the effectiveness of our after sales service. Our manufacturing facilities are based in the region of Nancy, France.

The quality of the manufacturing process and our R&D department enables us to meet the most complex requirements.

Our unique double rotor technology has been developed for extremely demanding requirements (reliability, high service factors, shock resistance). The double rotors make it possible to avoid fragile vanes by replacing them with gears made of treated steel.

These pneumatic motors are entirely machined in our workshops in France, which allows us to offer you customised solutions.